Galvanic Treatments

Offriamo trattamenti galvanici di alta qualità, tra cui cromatura, nichelatura, spazzolatura e satinatura, garantendo resistenza, durata ed estetica impeccabile. Questi processi non solo valorizzano i componenti, ma creano anche la base ideale per il successivo rivestimento PVD, assicurando un’adesione perfetta e una finitura uniforme e durevole.

CONVERSION FROM Cr VI to Cr III

The switch to Cr III chrome plating represents a significant evolution in terms of sustainability, regulatory compliance, and product quality. This process significantly reduces environmental impact by limiting harmful emissions and simplifying industrial waste management. It also lowers the risk of soil and water contamination, contributing to a safer and more eco-friendly production cycle.

At the same time, Cr III ensures greater compatibility with evolving environmental regulations, such as the REACH directive, which is progressively limiting the use of Cr VI. Adopting this solution ensures continuous production without the risk of future restrictions, maintaining high-quality standards.

From an aesthetic and functional standpoint, Cr III chrome plating offers excellent brightness and high resistance to corrosion, providing an appearance similar to Cr VI but with a significantly reduced environmental and health impact. This allows for high-quality finishes, combining durability, safety, and sustainability.

FINISHES AND PLANT

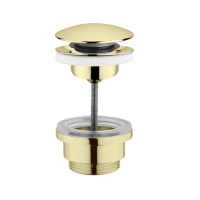

We offer several types of finishes, including chrome plating, nickel plating, brushing, and satin finishes. Each treatment is executed with the utmost precision to meet both aesthetic and functional needs, ensuring resistance and long-term quality.

Our semi-automatic plant has been designed to ensure superior quality control at every stage of the process. By working on a limited number of pieces per cycle, we can closely monitor the load and drain of the material, ensuring each component receives the optimal treatment. This approach helps prevent defects and guarantees a uniform and flawless finish.

PREPARATION FOR PVD TREATMENT

The galvanic treatment plays a crucial role in preparing the material for the subsequent PVD coating, as PVD does not cover surface defects but rather highlights them. To ensure a flawless result, starting with a perfect base is essential.

Through our galvanizing process, we create uniform, defect-free surfaces, reworking the material internally if needed.

Thanks to this combination of treatments, components acquire a refined appearance and superior protection against wear, scratches, and corrosion, ensuring excellent performance both aesthetically and functionally.